PRODUCING ENERGY FROM RENEWABLE SOURCES

The circular economy is based on a fundamental principle: recovering and reusing waste materials to feed new production cycles while minimizing waste.

The Water wall® technology makes it possible to recover, regenerate and reuse oils and hydrocarbons dispersed in aqueous wastewater without using chemicals. This process is in perfect accordance with the rules of the ecological economy where, in addition to production benefits, economic benefits are also taken into consideration as well as the environmental impact associated with an improvement of the environment. In fact, the removal of “tramp oils” from the coolants used in metalworking leads to the improvement of the working environment, avoiding the formation and dispersion of oil mists in the environment itself.

The reuse of the regenerated coolant fluid, in addition to having an important economic impact, allows one to obtain a positive environmental impact such as the remediation of contaminated sites, ensuring their compatibility with environmental preservation.

The activities of Technofluids encourage the green economy to improve the quality of life.

Technofluids wants to provide citizens with a highly innovative and technological proposal that brings benefits to the environment while creating economic development, new activities and new jobs. Ultimately, this will allow us to improve the economy of our country by reducing imports and exploiting the waste as a resource.

TTVM

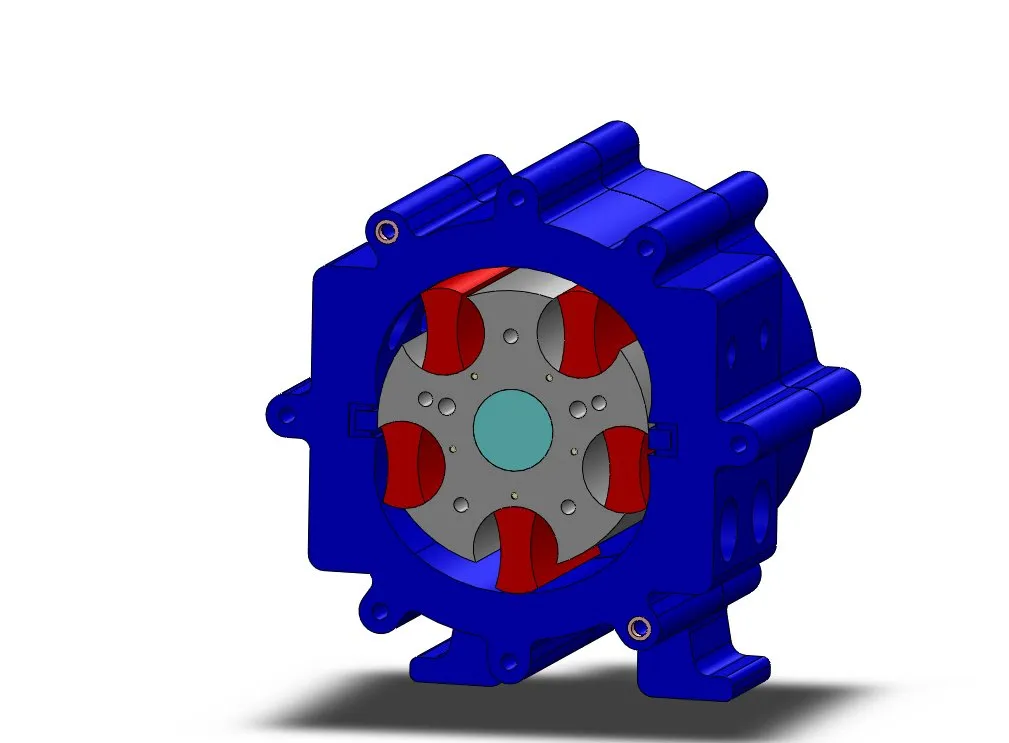

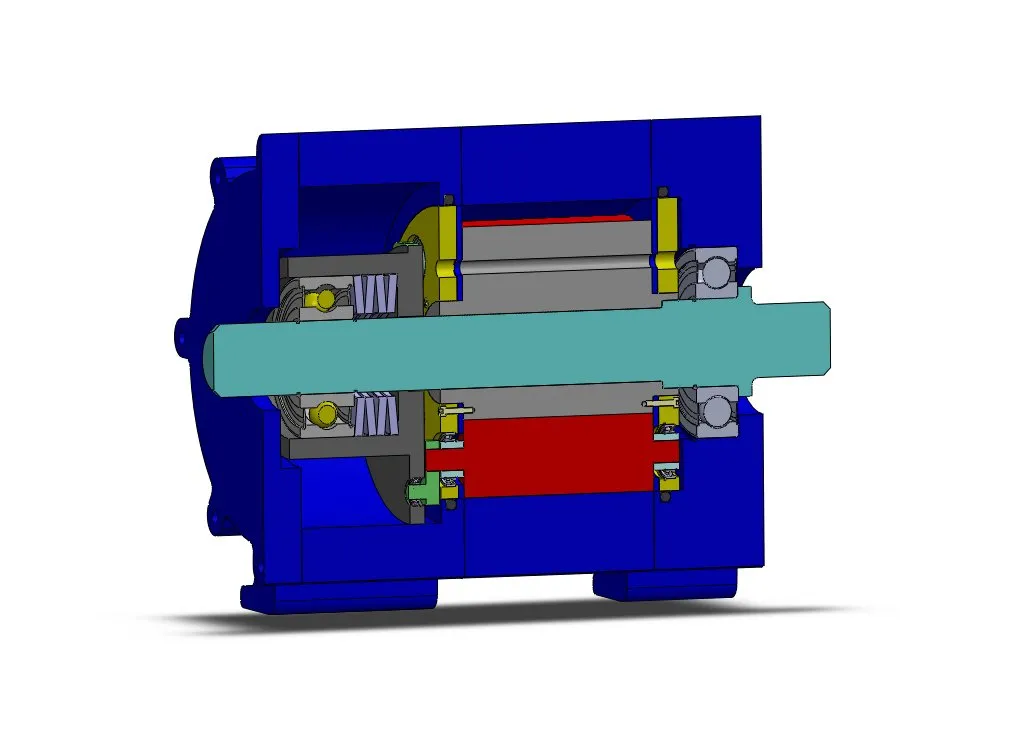

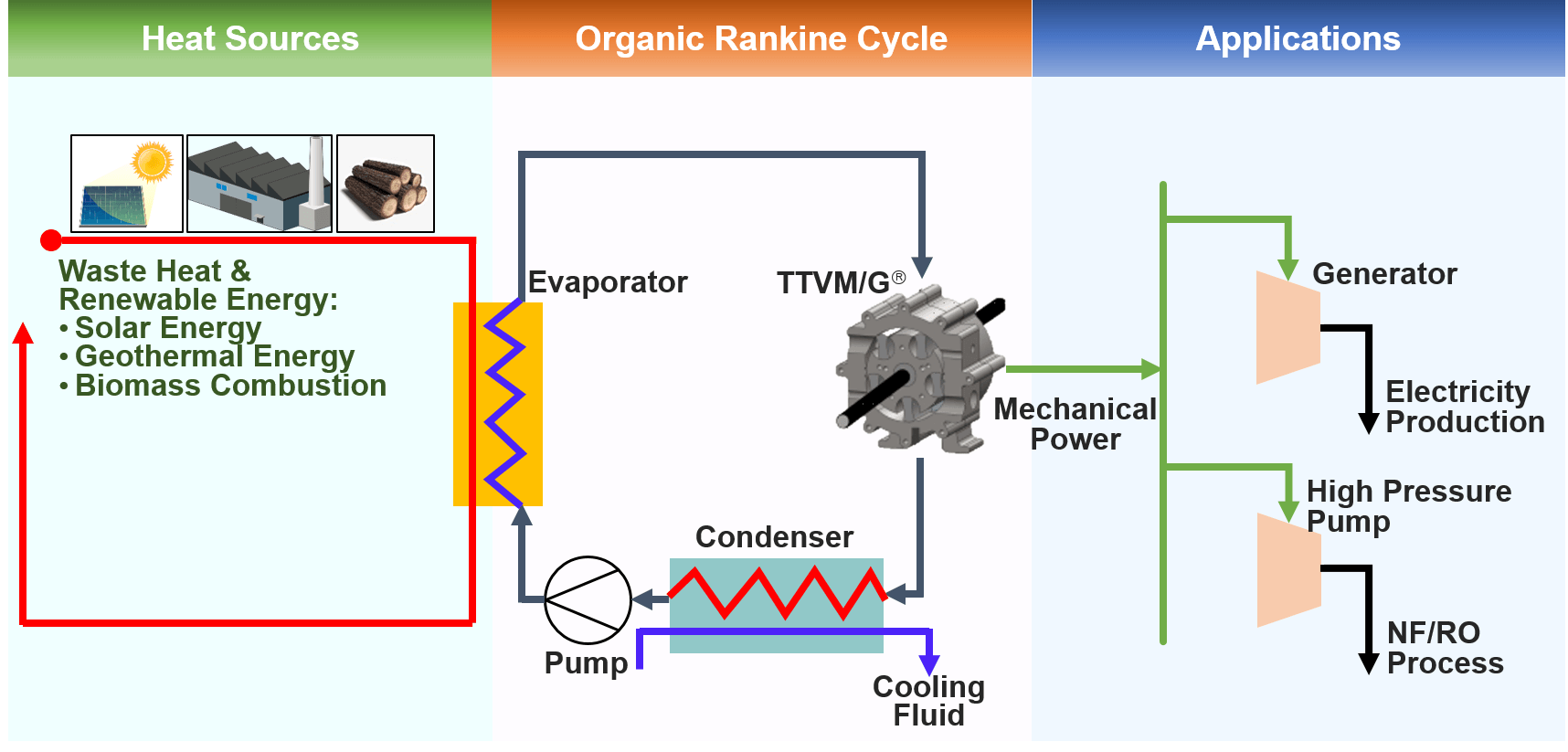

TTVM / G (Torini Thermo-Volumetric Motor / Generator) is a very compact rotating volumetric machine with multiple effects and low friction. Applied in ORC (organic Rankine cycle), TTVM / G shows high efficiency even with small temperature differences at low temperature. TTVM / G allows efficient energy production from low, medium and high temperature heat generated by renewable energy sources such as biomass combustion, solar and geothermal heat and waste heat sources from industrial areas.

TTVM / G offers the possibility to convert waste heat into electricity or mechanical power. Generating electricity from waste heat leads to lower energy bills and reduced harmful emissions. Mechanical power or electricity can activate desalination processes such as RO or CDI to produce fresh water. TTVM / G combined with concentrated solar energy, or waste heat, is emerging as the most promising solution for producing freshwater from seawater.

SPR

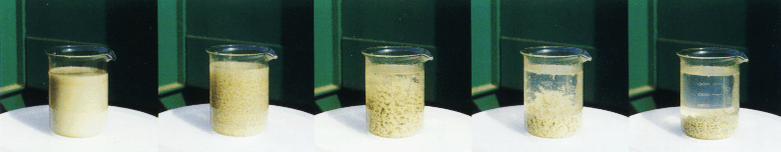

The Solvated Particles Removal (SPR) system is a process to purify polar liquid waste

The Solvated Particles Removal (SPR) system is a process to purify polar liquid waste

(i.e. water) containing colloidal dispersions of solvated particles. The resulting liquid from that

process is totally purified from these solvated particles and can therefore be reintroduced into the environment or recycled in the primary cycle of the industrial process, from which the liquid waste came, without undergoing further treatment.

The molecule used is natural, food grade and non-soluble. Consequently, it does not contribute to

increase the content of salts and / or impurities in the effluent.

SPR is also characterized by the fact that the treated liquid is not chemically altered in any way, as the molecule used is totally insoluble and therefore completely eliminated; these characteristics make it possible to reuse the clear liquids, obtained with the process of the invention, in the primary cycle from which the liquid waste has flowed out.

SPR can be effectively applied to all polar liquid waste containing solvated particles, regardless of the chemical nature of the particles, as the purification process involved is essentially a physical one.

The SPR process has also proved particularly useful for those effluents that must be subjected to nanofiltration, reverse osmosis or electrodialysis processes, because it allows to eliminate microfiltration and ultrafiltration treatments, to increase performance and extend the life of the relative membranes.